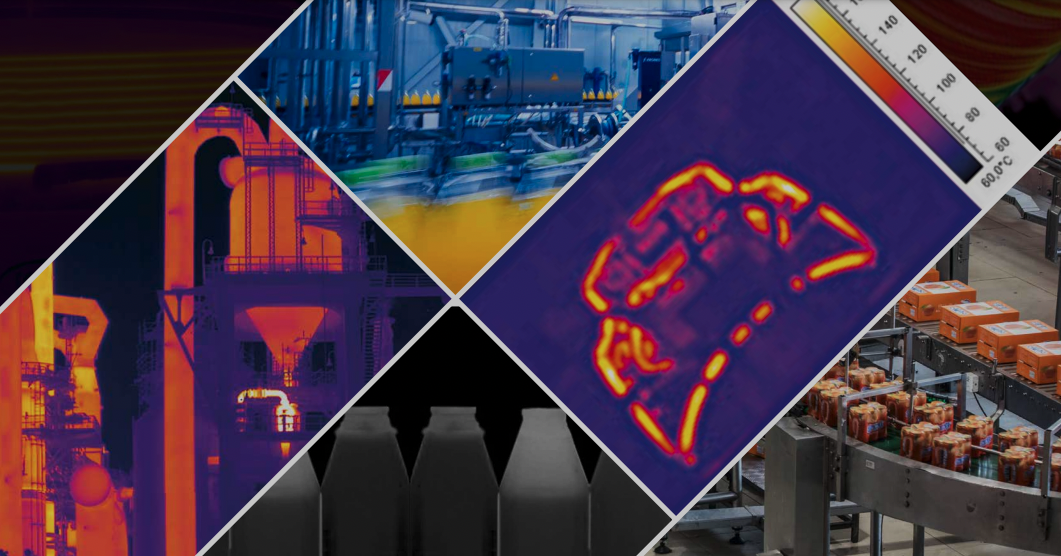

Fixed Thermal Cameras Improve Process Control and Quality Assurance

The use of plastic for parts such as dashboards and defroster grills is common throughout the automotive industry because these lightweight materials not only make vehicles more fuel efficient, but also allow for substantial design freedom and flexibility. These components are joined using infrared (IR) welding. While IR welding creates a strong bond, it's critical for manufacturers to ensure the welds reach the correct temperature and heat evenly. Otherwise the weld could fail, leading to expensive recalls.

IR welding for plastics

IR welding creates a high strength, hermetic seal using an infrared-emitting platen to melt the joining surfaces. The platen is then removed and the part halves are driven together and allowed to resolidify under pressure. Unfortunately, there is no visual way of telling whether the weld succeeded without stopping production for an inspection.

The solution to this quality monitoring issue is the use of thermal imaging cameras.

Monitoring the IR welding process with thermal imaging allows manufacturers to catch welds that fall outside the upper or lower temperature control limits.

An infrared camera set at a fixed position along the production line can repeatably and accurately illustrate the thermal patterns and gradients needed to identify flaws in IR welding. A thermal image can also show an incomplete shape, non-uniform temperature profile, or varying gradients. The temperature data collected from a thermal camera can help quality control engineers find and correct errors in the production line, preventing the output of defective products.

FLIR fixed-mount thermal systems such as A50/A70 Advanced Image Streaming cameras can stream temperature linear or compressed radiometric data through communication protocols such as GigE Vision and RTSP. These cameras offer up to ±2°C (±3.6°F) accuracy within temperature ranges of -20°C to 1000°C (-40°F to 3632°F), ensuring they provide correct, actionable data for quality control analysis. The A50/A70 Series offers two pixel resolutions (464 × 348 or 640 × 480) and a range of fields of view (29°, 51°, or 95°) on fixed lenses that you focus manually for a consistent view. Thanks to its unique compressed radiometric output, these cameras avoid overburdening processors. When paired with the optional built-in visual camera, the A50/A70 can produce FLIR-patented MSX® images that are easy for anyone to interpret.

Click to learn more about FLIR A50-A70 Image Streaming Cameras, or contact a FLIR expert for more information.