Gubba Cold Storage uses thermal imaging to guarantee best cold storage conditions.

Gubba Cold Storage offers its customers high-quality cold storage services for a wide range of products. In order to guarantee the best conditions for the stored goods, Gubba Cold Storage makes sure that its infrastructure is in an impeccable state. That is why the company recently invested in thermal imaging technology from FLIR. Thanks to FLIR, no insulation leakage or bad electrical wiring goes unnoticed.

Since 1987, Gubba Group Ltd. has been offering cold storage services out of Hyderabad, Andhra Pradesh, India. Gubba Cold Storage’s eleven cold storage units are operational on a 24/7 basis and offer infrastructure for stocking seeds, pharmaceuticals products as well as agricultural products. Every stored product in the cold storage facilities has its own set of prescribed temperature settings. Understandably, with the continuous operation of Gubba Cold Storage’s facilities lead to high energy consumption.

“At Gubba, we provide a host of value added services to our customers that helps build their trust,” says Gubba Prashant, director at Gubba Group Ltd. “As customer satisfaction is our main priority, we will do everything in our capacity to ensure that our customers’ stocks are preserved perfectly.”

Insulation leaks and humidity

To preserve the temperature in the cold storage units, the quality of insulation is of course of utmost importance. Leaks in the insulation material covering the cold storage unit can be a threat to the temperature uniformity inside the unit. However, insulation leaks used to be discovered in a rather random fashion and repaired on the fly. What’s more, insulation leaks can also allow moisture to enter the unit, which can also disturb the required relative humidity. The moisture that enters the building will condense and freeze. Eventually, the build-up of ice can also affect the insulation properties of the cold store wall and weaken the structure of the wall or building.

“I did not know about the power of thermal imaging, until I saw one of these cameras at work at a FLIR exhibition booth in India,” says Gubba Prashant. “There, I discovered that you can quickly scan large areas to look for insulation problems, find moisture beneath the insulation surface and much more. We decided to invest in one of FLIR’s handheld thermal imaging cameras and we haven’t regretted it ever since.”

Easy and timely detection

At Gubba Cold Storage , Gubba Prashant is now frequently using a FLIR i3 point-and –shoot camera to monitor the cold storage units and to detect possible leakages. One of the many advantages of this new approach is that inspections can now be scheduled in advance and on a regular basis. Small leakages can easily be detected before it escalates into something worse. And more importantly, by blocking these leakages in time, uniformity in temperature and relative humidity is maintained in the unit. This helps Gubba Cold Storage to save its customers’ stocks from perishing.

The FLIR i3 is the smallest, lightest and most affordable thermal imaging camera on the market from FLIR. It is incredibly easy to use and requires no former experience. It really is a matter of “point-shoot-detect” to obtain high-quality thermal images that will immediately give you the thermal information you need. It only weighs 365 g and is easy to store in a belt pouch.

Soft and hard benefits

“Again, next to safeguarding our facilities, doing regular inspections with our FLIR thermal imaging camera and sharing these thermal images with our customers also allows us to build trust,” says Gubba Prashant. “After performing a thermal audit with our FLIR i3 camera, we provide our customers with a report that certifies perfection in temperature and relative humidity maintenance.”

“But next to these intangible benefits, there are also hard benefits, such as enormous power savings and reduced energy bills, as a result of repairs we were able to do based on information from our thermal imaging camera.”

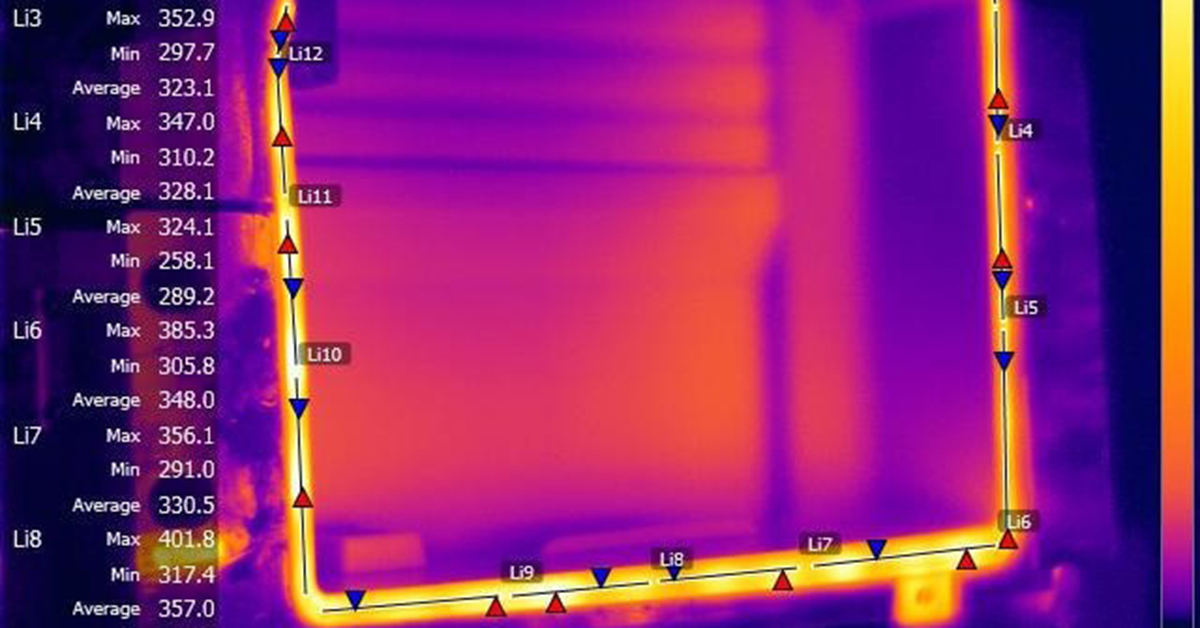

Electrical inspections

Aside from detecting heat and energy loss in cold unit storage structures, FLIR’s thermal imaging camera has proved to be an accurate & effective tool in Gubba Cold Storage’s facilities predictive maintenance programs. In electrical installations, hot spots in the thermal image usually point to emerging problems. With the FLIR i3 camera, Gubba Prashant’s team can now scan electrical cabinets and components and survey multiple wires and connections to get an instant picture of potential trouble.

“We use the FLIR i3 camera extensively for safety checks in electrical panels and chiller rooms across our various cold storage buildings,” says Gubba Prashant. “When the thermal imaging camera clearly shows you an electrical cable that is much hotter than its environment, you know you have to intervene. This is how we can prevent bigger problems from happening.”